The 6-Second Trick For Inventory Management

Wiki Article

The Basic Principles Of Inventory Management

Table of ContentsNot known Details About Inventory Management Inventory Management for Dummies10 Easy Facts About Inventory Management DescribedThe Best Strategy To Use For Inventory Management

JIT inventory administration can be high-risk. If demand all of a sudden increases, the supplier might not be able to source the supply it needs to fulfill that need, harming its credibility with customers as well as driving business towards competitors. Even the tiniest delays can be troublesome; if a crucial input does not get here "simply in time," a bottleneck can result.

The EOQ model seeks to make certain that the correct amount of supply is gotten per set so a company does not need to make orders also frequently and also there is not an unwanted of supply remaining on hand - Inventory Management. It thinks that there is a trade-off in between stock holding prices as well as stock configuration costs, and overall supply costs are minimized when both setup prices as well as holding costs are reduced.

DSI is also known as the average age of supply, days supply impressive (DIO), days in stock (DII), days sales in inventory or days supply as well as is translated in numerous ways. Showing the liquidity of the supply, the number stands for just how lots of days a company's present supply of stock will last.

Inventory Management Things To Know Before You Buy

If a company regularly switches its technique of stock bookkeeping without sensible validation, it is likely its monitoring is attempting to paint a brighter image of its company than what holds true. The SEC needs public companies to disclose LIFO get that can make inventories under LIFO setting you back similar to FIFO costing.This can additionally increase warnings with a firm's capability to remain affordable and also manufacture products that attract consumers moving forward. The four types of supply management are just-in-time monitoring (JIT), products demand preparation (MRP), financial order amount (EOQ), and days sales of inventory (DSI). Each stock management design functions better for different businesses, and there are pros and cons per type.

"Supply resembles dairy products," Chef is estimated saying. "Nobody wants to buy spoiled milk." Therefore, supply management can save a business millions. Let's check out an instance of a just-in-time (JIT) stock system. With this method, a company receives items as close as feasible to when they are actually needed.

Supply administration is a vital component of company operations. Appropriate supply management depends upon the sort of company as well as what kind of item it markets. There might not be one perfect kind of supply administration, because there are benefits and drawbacks per. Taking advantage of the most fitting type of inventory monitoring style can go a lengthy way.

Indicators on Inventory Management You Should Know

When it involves inventory administration, there's good information and there misbehaves news for lots of businesses. The trouble? Inventory monitoring can be a difficult task, which is why firms usually stay clear of re-evaluating their procedures. Right here's the bright side: If your company has supply of any kind of kind, you're likely sitting on special info a major possibility for organization development.While it might be tempting to adhere to a status-quo method, your stock management system can actually make or damage your company carrying out a reliable and also efficient system can be a surprise trick to success. Inventory Management. What is Stock Management? Continue reading to discover why inventory administration systems matter and also just how you can utilize the best system to assist your organization be much more efficient and lucrative.

Supply management, nevertheless, is even more than simply a simple tally of supply. A well-managed stock system lets your company maximize its storage rooms, far better offer consumers by having read what he said the supply that they want (when they desire it), as well as save money by lowering prices and also losses due to spoilage as well as theft.

Effective stock management can be a helpful device, offering insight right into vital elements of your company, including: Your financial standing, Consumer behavior, Item as well as organization possibilities, Future fads To reveal the power of supply monitoring systems on service success, let's count on the striking example of Kmart as well as Walmart during their rate battle in the 1990s - Inventory Management.

The Best Strategy To Use For Inventory Management

Their appropriately named "just-in-time inventory" system reduced excess supply, which liberated cash that might then be invested right into service growth. Additionally, this more-efficient system given much better understanding right into consumer needs that made it possible for the company to use even more of the items that clients wanted at a lower cost and also a reduced price for consumers.Throughout the same time duration, Kmart stuck with their typical supply administration process. The company submitted for insolvency this link in 2002, closed hundreds of Kmart stores, and also inevitably combined with Sears Roebuck in 2005.

While the details type of supply that your transaction with may vary considerably depending on whether your company is concentrated on wholesale, retail, or manufacturing, the essential concepts of how you handle inventory are universal. If we think about stock as cash, taking control of your supply and also maximizing what you have (while decreasing supply aka cash waste) is key.

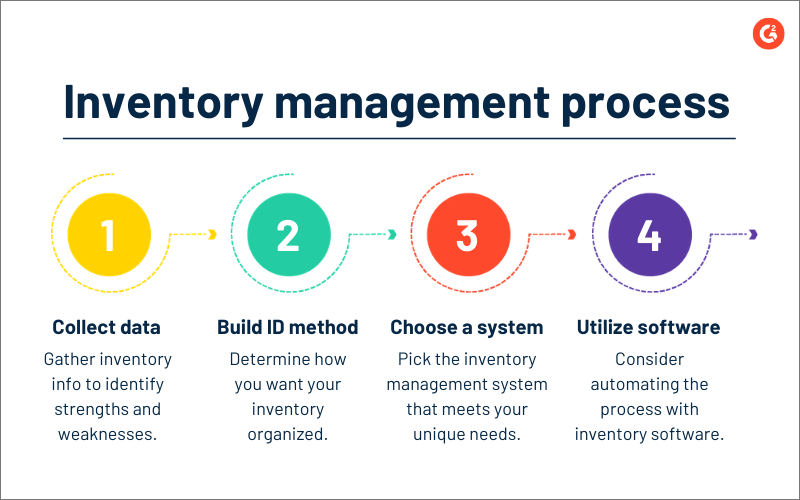

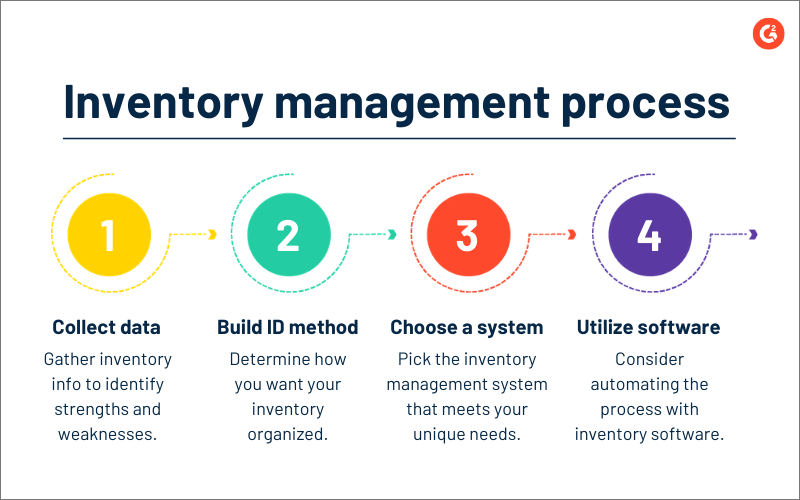

In order to develop higher visibility of supply levels, an effective stock management system should utilize factors like: You'll also want to examine the sort of inventory administration system you utilize as this can influence just how well you see your stock. In order to better comprehend how well your inventory system is serving your service, allow's look at two key methods to managing your inventory: regular and also continuous supply systems.

Report this wiki page